- Aviation

- 20 kL Cryogenic Liquid Medical Oxygen Vertical Storage Tank

- 10 kL Cryogenic Liquid Medical Oxygen Vertical Storage Tank Rafi Ahmad Kidwai Memorial District Hospital Barabanki UP

- 10 kL Cryogenic Liquid Medical Oxygen Vertical Storage Tank at MMG Hospital, Grand Trunk Rd, nr. Ghanta Ghar, Bihari Pura, Sarai Nagar, Naya Ganj, Ghaziabad, Uttar Pradesh 201001

- 10 kL Cryogenic Liquid Medical Oxygen Vertical Storage Tank at District Hospital Rampur UP Rajdwara Near State Bank of India 244901

- 10 kL Cryogenic Liquid Medical Oxygen Vertical Storage Tank at District Combined Hospital, Near Nahar Patri, village Mundet, Shamli UP 247776

- 10 kL Cryogenic Liquid Medical Oxygen Vertical Storage Tank at District Combined Hospital Hathras U.P.

- 10 kL Cryogenic Liquid Medical Oxygen Vertical Storage Tank at Combined District Hospital Mau U.P.

- 10 kL Cryogenic Liquid Medical Oxygen Vertical Storage Tank at Dr Ram Manohar Lohia Male Hospital Farrukhabad UP

- 1000 Bar Hydraulic Proof Pressure Test Bench

- 20 kL Cryogenic Liquid Medical Oxygen Vertical Storage Tank

- 45 Degree Left And Right Moment Durability Test Rig

- ACM-test-bench

- Advance Valve Pressurepac-900 Bar

- Aero Engine Preservation

- Aircraft Arrester Barrier system Suratgarh

- Aircraft Arrester Barrier system Jamnagar

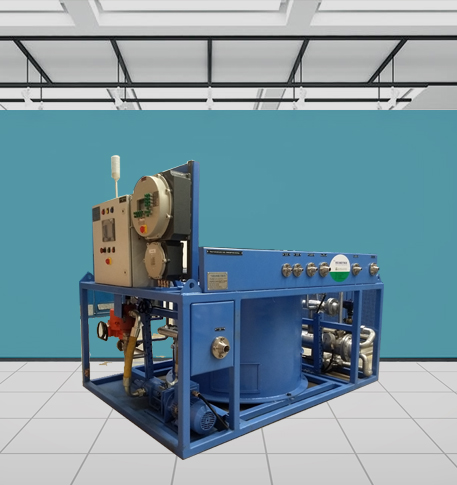

- Argon Heating and Cooling System

- Automated Inverter Test Rig On Labview Environment

- Automatic Volumetric Expansion Test System

- 70000 RPM Bearing Test Rig

- BMP Pump Test Rig

- Bomb Shell Hydraulic Pressure Testing Machine Upto 1800-Bar

- Capacitor Inspection System

- CCB Burn Test Rig

- Chemical Cleaning Bay

- CNG Circuit Leak Tester

- CNG Circuit Leak Testing Machine for Volvo Buses

- CNG High Pressure Regulator Test Bench

- CNG Regulator Test Bench

- CNG Vigilant

- CO2 & N2 Filling System

- cold air unit test bench

- Combined Control Unit Test Bench

- computerized control universal brake test bench

- Daq Sytem For Filter

- Distributor Valve Test Rig

- DOPPLER VOR TEST RACK

- Dual Hydraulic Test System

- ECS-test-bench

- Fuel Consumption Measurement System

- Fuel Injection Pump Test Bench

- Fuel Pump Test Rig

- Fuel (ATF) Pump Test Stand

- Gas Cabinets

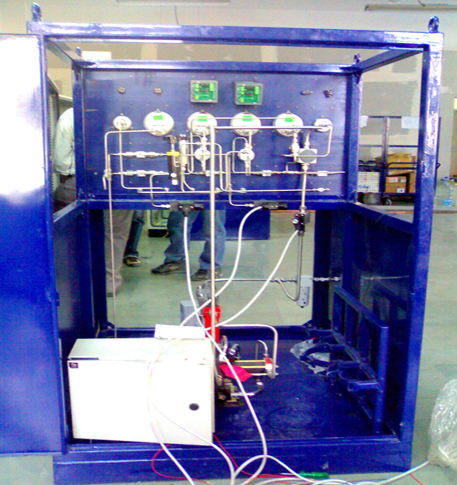

- Gas Distribution System

- Gas Purging System

- Greenfuel-CNG Gas Flow Meter

- HAL BLR - Universal Hydraulic Test Rig

- Halon Reclaimation And Refiling Facility

- Head Impact Test Rig

- Helium Charging Station

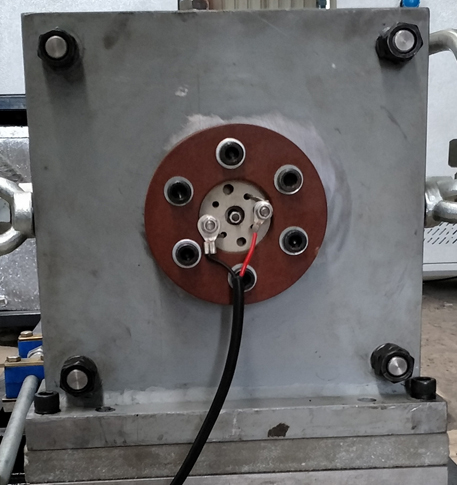

- High Pressure Test Rig

- Hose Test Bench

- Hydraulic Control Valve Test Bench

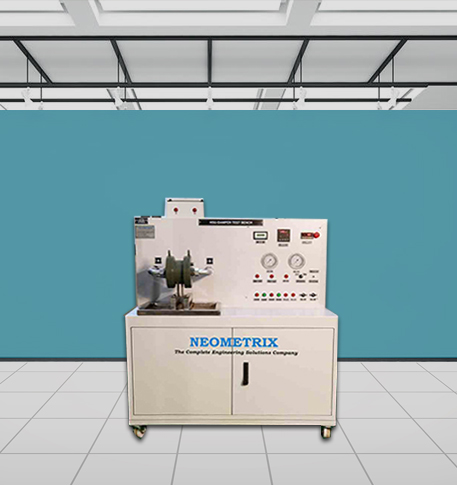

- Hydraulic Damper Test Bench

- Hydraulic Direction Unit Test Bench

- Hydraulic Flushing Rig

- Hydraulic Powerpack and Actuator System

- Hydraulic Pressure Test Bench

- Universal Hydraulic Service Trolley HST-300U

- Hydraulic Snubber Test Bench

- Hydraulic Suspension Unit Test Bench

- Hydraulic Test Pac With Chart Recorder

- Hydraulic Test Rig Hs-748

- Hydraulic Test Rig Of Rear Cover Sub Assembly

- Hydraulic Manifold

- Hydrogen Gas Boosting Station

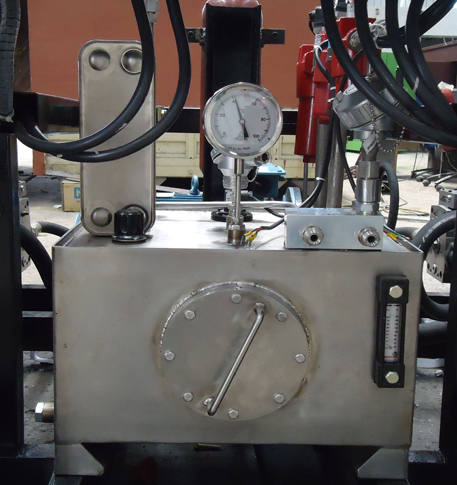

- Hydrostatic Test Bench

- Hypoxic Gas Generators

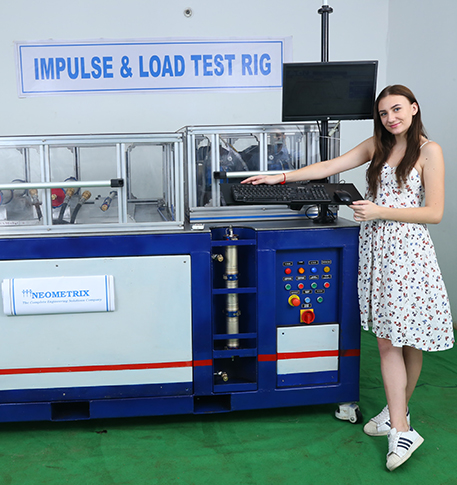

- Impulse & Load Test Rig

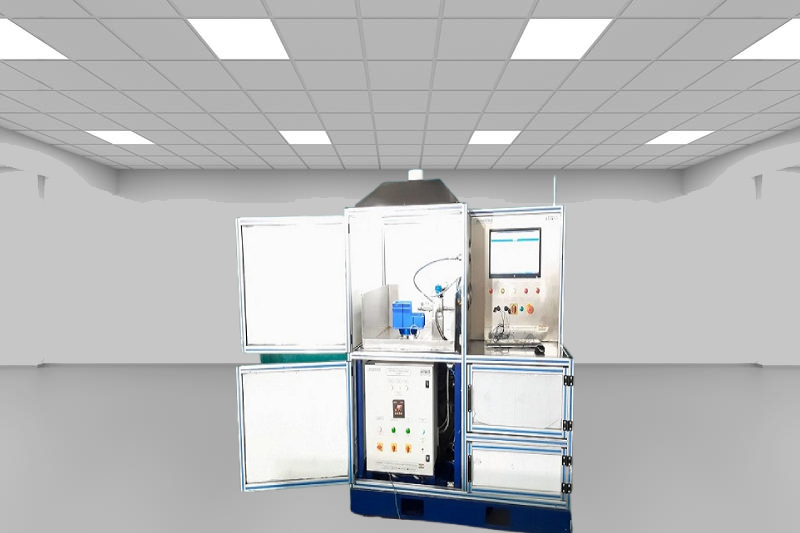

- Impulse Testing Machine For Hydraulic Hoses

- Inertia Test Facility

- KU-7 Oxygen Tester

- Loading Rig

- Main Rotor Actuator Test Rig

- Measuring Wheel Project

- Nitrogen cart with Booster

- Nitrogen Gas Boosting Station

- Nitrogen Purging System

- Oxygen Boosting System for Oxygen Generation Plant-PSA

- Oxygen charging and distribution vehicle-UGSSO2

- Oxygen Gas Boosting Station

- PLC Controlled Autoclave Pressure Tester

- Pneumatic Test Rig

- Portable oxygen concentrator 10 LPM

- Portable Cylinder Nitrogen Trolley With Booster

- Power Shuttle Transmission Test Rig

- Pressure Cycle Test System

- Pressure Loss And Leak Test Rig

- Pressure Pac

- Pressurization of Test Tubes

- Priority Panels

- PSA-medical-oxygen-generation-plant-babu-eswar-sran-district-hospital-gonda-U.P.

- PSA medical oxygen generation plant CHC badi sadri chittorgarh rajasthan

- PSA Medical Oxygen Generation Plant Chc Chaurmastpur Ambala Haryana

- PSA Medical Oxygen Generation Plant CHC Dabi Bundi Rajasthan

- PSA Medical Oxygen Generation Plant CHC Dei Bundi Rajasthan

- PSA Medical Oxygen Generation Plant CHC Dungla Chittorgarh Rajsthan

- PSA Medical Oxygen Generation Plant CHC Hindoli Bundi Rajasthan

- PSA Medical Oxygen Generation Plant CHC Hospital Hati Kanpur Dehat

- PSA Medical Oxygen Generation Plant CHC Hospital Malsisar Rajasthan

- PSA Medical Oxygen Generation Plant CHC Hospital Mandalgarh Rajasthan

- PSA Medical Oxygen Generation Plant CHC Jaysinghpur District Sultanpur Uatter Pradesh

- PSA Medical Oxygen Generation Plant CHC Kapasan Chittorgarh Rajasthan

- PSA Medical Oxygen Generation Plant CHC Lambhua District Sultanpur Uatter Pradesh

- PSA Medical Oxygen Generation Plant CHC Sankoo Kargil Ladakh

- PSA Medical Oxygen Generation Plant CHC Saraswati Nagar Namunanagar

- PSA Medical Oxygen Generation Plant CHS District Hospital Kargil Ladakh

- PSA Medical Oxygen Generation Plant District Combined Hospital Kushinagar

- PSA Medical Oxygen Generation Plant District Combined Hospital Sanjay Nagar Ghaziabad

- PSA Medical Oxygen Generation Plant District Combined Hospital Shikohabad Firozabad

- PSA Medical Oxygen Generation Plant District Hospital Dakor Kheda Gujrat

- PSA Medical Oxygen Generation Plant District Hospital Katihar Bihar

- PSA Medical Oxygen Generation Plant District Hospital Maternity Wing Bijnor

- PSA Medical Oxygen Generation Plant District Hospital Maternity Wing Bulandshahr

- PSA Medical Oxygen Generation Plant District Male Hospital Hardoi

- PSA Medical Oxygen Generation Plant District Male Hospital Jalaun

- PSA Medical Oxygen Generation Plant District Women Hospital Bareilly

- PSA Medical Oxygen Generation Plant State Cancer Hospital Jaipur Rajasthan

- Oxygen Changeover Panel PSA To Manifold, For Gas Distribution

- PSA Medical Oxygen Generation Plant District Women Hospital Mainpuri

- PSA Medical Oxygen Generation Plant CHC Dei Bundi Rajasthan

- PSA Oxygen Generation Plant GMHC Bettiah Near Rama Maidhan West Champaran

- PSA Oxygen Generation Plant GMHC Bettiah Near Rama Maidhan West Champaran

- PSA Oxygen Generation Plant GMHC Bettiah Near Rama Maidhan West Champaran

- PSA Medical Oxygen Generation Plant Maharaja Suhel Dev Autonomous Medical College & Hospital Bahraich, U.P.

- PSA Oxygen Generation Plant Military Base Hospital Lucknow U.P.

- PSA Medical Oxygen Generation Plant Military Hospital Allahabad U.P.

- PSA Oxygen Generation Plant Military Hospital Danapur Patna

- PSA Medical Oxygen Generation Plant CHC Dabi Bundi Rajsthan

- PSA Medical Oxygen Generation Plant Sub District Hospital Dhamdaha, Purnia, Bihar

- PSA Oxygen Generation Plant CHC Saraswati Nagar Yamunanagar

- PSA Oxygen Generation Plant Railway Hospital Secundrabad (Nanded)

- PSA Oxygen Generation Plant Military Hospital Fatehgarh Farrukhabad

- PSA Oxygen Generation Plant Military Hospital Golconda Langar Houze Hyderabad

- PSA Medical Oxygen Generation Plant Sub District Hospital Dwarka Gujrat

- PSA Medical Oxygen Generation Plant Sub District Hospital Morbi Gujrat

- PSA Oxygen Generation Plant Sub Divisional Civil Hospital Jakhalabandha Asam

- PSA Oxygen Generation Plant Swahid Kushal Konwar Civil Hospital Golaghat Asam

- PSA Medical Oxygen Generation Plants

- PSA Nitrogen Generation Plant

- Refrigeration System

- Refrigerator Door Endurance Testing System

- Rotor Dynamics Test Facility at AERDC

- Servo Hydraulic Actuators

- SF6 Recovery & Charging Trolleys

- CNG High Pressure Regulator Test Bench

- Starter Generator Test Rig

- Supply of Suction Lubrication System for 1000HP Cyclic Spin Test Facility

- Valve Test Rig

- Universal Hydraulic Test Rig

- Universal Hydraulic Service Trolley

- Universal-Hydraulic-Charging-Rig-Nasik

- Through Hole Inspection

- Test Rig For IRAB Brake System

- Test Pac

- Test Pac Digital

- TACAN Test Bench

- Test Rig For A9 Automatic Brake Valves

- Test Rig For SA9 Automatic Brake Valves

- Test Rig For C2W Relay Valves

- Test Rig For C2W Relay Valve 6mm Chock Valves

- Test Rig For MU-2B Valves

- Test Rig For F1 Selector Valves

- Test Rig For N1 Reducing Valves

- Test Rig For Feed Valve C2N-FT1 Combined Feed Valves

- Test Rig For C2W Distributor-brake-valves

- Test Rig For Duplex Check Brake Valves

- Test Rig For GM Type Drain Valves

- Test Rig For 24-A Double Check Valves

- Test Rig For R-6 Relay Valves

- Test Rig For Air Flow Measuring Valves

- Test Rig For J-1 Safety Valves

- Test Rig For Emergency Brake Application Valves

- Test Rig For Pressure Switch Valves

- Test Rig For Magnet Valves

- Computerized Based Test Bench For Panel Mounted Brake System For LHB Coches

- Distributor Valve Test Rig

- DV Test Rig

- Hydraulic Power Pack 230lpm/210 Bar

- Liquid Oxygen Dispenser 800 Ltr along With Towable Trolley

- CCTV Surveillance System Including Sensor For Infrastructure Protection

- Hydraulic Flushing Rig Nigeria

- Computerized Microprocessor Controlled Dv Test Bench

- CM Transportation Modules

- Universal Hydraulic Test Bench Aircrafts

- Hydraulic Refilling Trolley

- Drive And Control Automation System

- Modern Universal Automatic Test Equipment

- PSA Medical Oxygen Generation Plant 2400 LPM Jammu Kashmir

- 10 kL Cryogenic Liquid Medical Oxygen Vertical Storage Tank AIIMS Rishikesh Uttarakhand

- Mobile Test Facility for Aircraft Engines

- PCB Functional Test Bench

- Optical Test Bench For PCB And Optic Testing

- PCB Thermal Test Bench

- Ground Power Unit (GPU)

- Starter Generator Test Bench for Advanced Light Helicopter

- Lock Loading Test Rig

- Test Rig for 130LPM Pump of LCA

- Hydraulic Hose Leak Test Rig

- Hydraulic Loading System

- Dynamometer Engine Test Rig

- Digital Barometer

- Test Rig For Hydraulic Fluid

- Neometrix Optical Balloon Theodolite

- E-148 Sector-63,

Noida, Delhi-NCR, UP, India -

Sales & Service - +91 7777-876-876

+91 (0120) 4500-800 (100 Lines)